Use of LNG

The use of LNG in heavy land transport began in Italy in 2014 with the first service station in Piacenza, a hub for major long-distance transport companies, while dozens of refueling points already existed in the rest of Europe at the time. Italy caught up and in 2019 became the leader in Europe in terms of the number of service stations and trucks on the road.

The LNG refuelling service stations are equipped with a cryogenic tank for storing liquid natural gas which is delivered directly to trucks and in the form of compressed gas to cars.

New LNG heavy vehicles have the same performance as vehicles powered by traditional fuels: LNG trucks can travel up to 1,600 kilometres on a single tank.

REFUELING STATIONS IN ITALY

Today in Italy there are more than 120 service stations that supply over 4,000 trucks, for a consumption of approximately 300,000 cubic meters / year of LNG (130,000 tons / year). Italy represents about 25% of the European market.

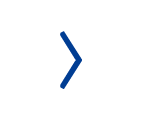

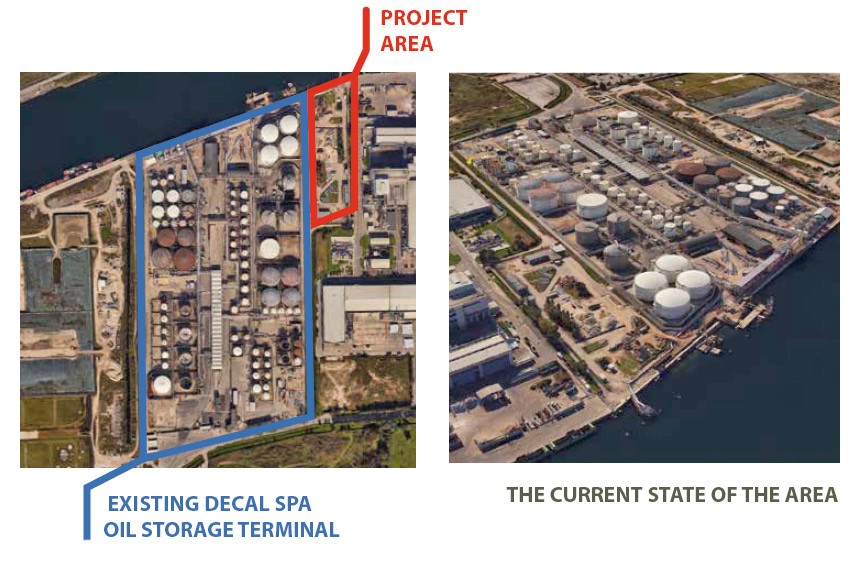

This result has been achieved despite the lack of coastal LNG storage facilities in Italy until a few weeks ago: operators had to refuel in France, Spain, or Northern Europe, with a material increase in costs.

The higher procurement spending determines a strong imbalance between the North, which is home to 64% of LNG distributors, the Centre, with 25%, and the South, with 11%. Rebalancing this scenario will only be possible with new storage facilities, such as Venice LNG.

PERSPECTIVES FOR THE FUTURE

By the time Venice LNG will be operational, in 2025, approximately 250 service stations and 8,500 trucks are expected to circulate in Italy, for a consumption of approximately 700,000 cubic meters.

By the same year, there will be about 1,000 service stations and about 35,000 trucks in Europe, for a consumption of about 3 million cubic meters. This market is expected to grow strongly in Central-Eastern Europe, an area of extreme interest for Venice LNG.

The first LNG vessel, excluding large LNG carriers, entered service in the Baltic Sea in 2013. Since then, orders have grown steadily with a strong acceleration since 2019.

LNG seafaring is today the most modern and the least impacting on the environment. Cruise ships, container ships, oil tankers, merchant ships and ferries are powered by LNG, supplied directly by small tankers or by tanker trucks from port docks.